| |

| |

|

|

|

| |

Visit to HML Lalru, Mohali (07April 2012)

– A Brief Review |

|

The Indian Institute of Metals – Delhi Chapter regularly organizes visits to eminent industries in

and around NCR, for benefit of its members. In this series, a team of IIM DC members visited

Hansa Metallics Ltd., Lalru, Mohali on 07April 2012, on initiative of IIM-DC members. The visiting

members went around modern facilities of HML and had extensive deliberations with the senior

officials. Mr.S.L.Saini, General Manager of the Plant, personally took around Team members and

explained working of different Units. |

Hansa Metallics Ltd., Lalru is a

Family owned, modern Tube making

facility. The Company was

incorporated in 1997 and the plant

was set up at the present location,

with Headquarters in Industrial Area

I, Chandigarh. The plant has inhouse

facilities for Cold Rolled steel

strips & foils and High frequency

ERW Precision Tubes. Mr. Surinder

Garg CMD, is the head of

Organization

. |

|

|

| PLANT FACILITIES |

| Process |

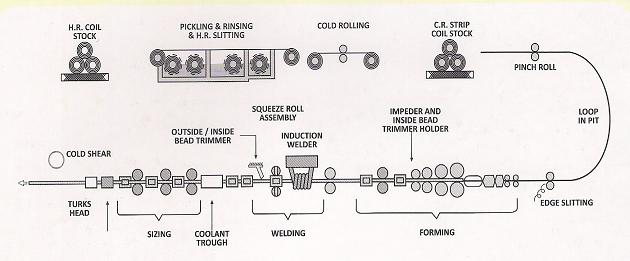

Hot Rolled (HR Coils) are received, by road from Integrated Steel Plants (Bokaro Steel Plant). Coils are sent thro’ Pickling & Rinsing Line and Cold Rolling for cleaner finish and achieving precise |

thickness for further

processing. Cold Rolled strips are

then sent thro’ annealing under inert

atmosphere. The Bright Annealing

Furnace has been supplied by

Technotherma India Pvt. Ltd.

Annealing temperatures vary

between 640 - 710

o

C depending

upon the carbon content of the coil.

Annealed strips are then sent to

slitting unit to achieve exact width

for final processing. Slits are then

finally processed in the Tube making

Unit by forming, induction welding

and sizing stages. Tubes are then

cut by a cold shear and are bundled

for dispatch to consuming industries. |

|

|

| A broad process flow is given below: |

|

| Cold Rolling & ERW Tube Manufacturing Process |

| Facilities |

- Continuous pickling line for HR Coils

- 6 high Cold Rolling Mill 1000 mm width with Automatic Gauge Control Device

- Separate slitting line of HR/CR Coils

- Bright Annealing Furnaces

- 5-Tubes Mills to produce from 12 mm to 110.5 mm diameter facility, equipped with Cold Saw

- D.M. water plant for quality product

- Physical laboratory for Mechanical Properties and dimensional measurements

|

| Products |

- Electrical Resistant Welded Plain Carbon steel tubes – OD 12.7 to 114.5mm, thickness

0.71 to 4.5 mm, up to 8 meter long - Cycle, automotive, furniture and general

engineering applications

- Electrical Resistant Welded Square Hollow Sections – Size 19 to 50mm, thickness 0.71 to 4.5 mm, up to 8 meter long - Automotive, furniture and general engineering applications

- Electrical Resistant Welded Rectangular Hollow Sections – Size 40x20 to 80x40mm,

thickness 0.71 to 4.5 mm, up to 8 meter long - Automotive, furniture and general

engineering applications

- Electrical Resistant Welded Oval & Elliptical Hollow Sections – Size 20x60 to 57x27mm

(oval) and 29x61 to 32x52 mm (elliptical), thickness 0.71 to 4.5 mm, up to 8 meter long

- Cycle, automotive, furniture and general engineering applications

|

| INTERACTIONS WITH SENIOR OFFICIALS |

Activities of IIM Delhi Chapter were discussed. Copies of IIM-DC Monthly Newsletter, IIM-DC

Brochure and MMMM2012 Conference Brochure were handed over. Senior officials of HML were

invited to participate in MMMM2012 Conference and Exhibition. |

The visit to Hansa Metallics Ltd. Lalru ended with thanks to their senior officials for facilitating

this visit. |

|

|

|

|

|

|

|

| |

|

|